Electronic connectors, also known as electrical connectors, are equipment used to join two or more electrical circuits together by conducting electricity between them. Electronic connectors may come in different forms, depending on how you define them. First, electronic connectors can be individual pieces of equipment working to complete the circuit connection. Second, electronic connectors can be a set of connectors working together, like a joined male and female connector set. They can also be any other form of electrical terminal. Also, the circuits themselves can be in the form of cable, or one can be a cable and the other can be an electrical terminal. Read More…

Aries Electronics Inc. manufactures electronic interconnect products and other electronic components. Some products include zero insertion force test sockets, intelligent connectors, adapters, ball grid array sockets, land grid array sockets, high-frequency test sockets, and burn-in sockets.

Interpower is a company that is committed to providing industries with high-quality products. We manufacture electronic connectors. We make it easy for customers to design, build and maintain products for worldwide markets. We use teamwork to provide fast turnaround and great service to our customers.

Quail Electronics is a leading supplier of electrical components such as power cords and appliance electronic connectors. If you don't find what you need in our stock items, we can customize a product to meet needs.

Kord King manufactures world class electronic connectors, electric cords and plugs, electrical receptacles, plug adapters, cord sets and much more. From initial design to development, whether you are looking for a cable assembly or a power supply cord, the experienced team at Kord King delivers rapid order turn-around times and excellent products – consistently adhering to our strict quality...

Since 1977, we have manufactured electronic connectors, RF connectors, card edge connectors plus cable assemblies. Nemal Electronics' products are used in broadcast, data, electronic control and RF applications. We have a stock of DIN connector products or we can custom make what you need.

UI is an authorized distributor of high-quality electronic components. Through a variety of product lines, we offer items such as electronic connectors including cable connectors as well as capacitors, switches, relays, terminals and more. We are a NEDA Supplier Authorized Distributor.

More Electronic Connector Manufacturers

Applications

Electronic connectors play a crucial role in various industries and applications, serving as vital components for reliable and efficient connections. In PCB connectors for printed circuit boards, these connectors ensure seamless integration and electrical continuity between different components on the board. They enable the transfer of signals, power, and data between various modules, making them essential in electronic devices ranging from smartphones and tablets to PCs and laptops.

DIN connectors, popularly used in loudspeakers, ensure secure connections between audio equipment. They offer standardized connections, reducing the risk of misalignment or incorrect connections, leading to enhanced audio performance. These connectors are also found in audiovisual equipment, televisions, and electric guitars, where robust and high-quality connections are essential for optimum sound reproduction.

Connectors designed to meet military specifications are built to withstand harsh environments and rigorous conditions. These rugged connectors are utilized in military equipment to ensure dependable communication, data transmission, and power distribution in demanding scenarios. Their resistance to extreme temperatures, moisture, and mechanical stress makes them indispensable in critical military applications.

In the consumer industry, meanwhile, electronic connectors are ubiquitous in everyday devices like cell phones, tablets, and telecommunications equipment. They enable charging, data transfer, and interfacing with peripherals, contributing to seamless user experiences. Additionally, connectors used in the medical industry adhere to strict standards for safety and reliability. They are employed in medical devices and equipment, ensuring accurate data transmission and uninterrupted power supply in critical healthcare settings.

The automotive industry also heavily relies on connectors for various applications, from engine control units and infotainment systems to sensors and lighting systems. These connectors facilitate efficient communication between different components in modern vehicles, enhancing their functionality and safety.

Commercial industries additionally utilize connectors for diverse applications, such as data centers, industrial automation, and robotics. In data centers, connectors enable quick and reliable connections between servers, networking equipment, and storage systems, ensuring seamless data transmission. In industrial manufacturing, connectors are employed in control systems, machinery, and sensors, supporting efficient and automated processes.

Overall, electronic connectors are versatile components that underpin modern technology across a wide range of industries. They ensure smooth and reliable communication, power delivery, and data transfer, making them integral to the functionality and performance of numerous electronic systems and devices. From consumer electronics to military-grade equipment, these connectors are fundamental building blocks of our interconnected world.

How They Work

Electronic connectors play a crucial role in establishing reliable connections between electronic components and devices. They work by providing a secure physical and electrical interface between male and female connector parts. These connectors are designed with specific pins or terminals that align and make contact when mated, creating a conductive path for electrical signals or power to pass through.

The mating process is generally user-friendly, often incorporating guiding keys or polarization to ensure proper alignment, reducing the risk of misconnection. The connectors also feature a mechanical lock when mated, preventing accidental disconnection due to vibrations or movement.

Inside the connectors, electrical contacts made of conductive materials like copper, gold, or silver facilitate efficient signal transmission with low resistance. These contacts are engineered to maintain a stable connection, even in challenging environmental conditions such as temperature fluctuations, humidity, or mechanical stress.

The relevance of AC (Alternating Current) and DC (Direct Current) currents in the context of electronic connectors lies in the type of application they serve. AC currents periodically reverse their direction, constantly changing polarity. Connectors designed for AC applications must consider factors like impedance, capacitance, and inductance to ensure minimal signal distortion and efficient power transfer. AC connectors are commonly found in devices that require high-frequency data transmission, power distribution, and applications such as audio and video equipment.

On the other hand, DC currents flow in a constant direction without reversing polarity. Connectors used for DC applications focus on ensuring low resistance to maintain steady power delivery and reliable data transmission. DC connectors are prevalent in applications like power adapters, battery-powered devices, and digital data transfer systems.

The choice between AC and DC connectors is essential, depending on the specific needs of the application. They are designed to cater to the unique requirements of different electronic systems, allowing for optimized performance, efficiency, and safety.

In summary, electronic connectors serve as indispensable components in modern technology, establishing reliable connections between electronic devices. They facilitate efficient signal transmission and power delivery by providing a secure interface between male and female parts. Additionally, the relevance of AC and DC currents lies in the specific application each type of connector serves. AC connectors are suitable for high-frequency data transmission and power distribution, while DC connectors are ideal for steady power delivery and digital data transfer. The careful consideration of these factors ensures the optimal performance and functionality of electronic systems in various industries and applications.

Design

When designing an electronic connector, manufacturers must think about a number of different factors. First, they must consider the environment that the electronic connector must work in and they have to think about things like:

- To what the electronic connector must connect

- The maximum and minimum surrounding temperatures

- What level of mechanical stress can they expect the connector to experience

- Whether or not there are any existing connectors with which the new connectors must be compatible

- Whether or not the user will be frequently plugging and unplugging the connector, etc.

Based on these considerations, among others, electronic connector manufacturers will decide on technical details like pitch (distance between the respective centers of separate connector contact pieces, both female and male), durability/mating cycles (the length of time you can expect your connector to last if you use it normally), versatility, voltage type, current type, etc. Manufacturers must also decide on electronic connector sizes and materials.

To increase the versatility of an electronic connector, manufacturers can add custom features such as extra contacts, adaptability features, seals between the enclosure and insert (to protect against oil, water, and other moisture), corrosion-blocking anodized shells, and/or strain relief features. (Strain relief features keep harmful mechanical forces from reaching the electronic connector.) To customize an electronic connector, manufacturers can also change the number and types of pins it has. Learn more about the possibilities of custom electronic connector design by talking with your potential suppliers.

Features

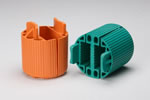

There are many different kinds of electronic connectors. However, in general, they feature a few key parts. These include contacts or terminals, a housing, locking features, and keying features.

Contacts or terminals are the parts of the connector that create the actual connection. Male connector contacts are also often called “pinouts” because they are generally extended metal pieces, like pins or prongs.

The contact system is one of the most important parts of an electronic connector because it establishes the density requirements, contact forces, and other mechanical features of the connector.

Manufacturers make contacts and terminals almost exclusively from highly conductive non-corrosive metals, such as phosphor-bronze, beryllium copper, modified copper, or brass.

Housings encase the contacts and protect them from exposure to or collision with outside elements or people. Typically, manufacturers make housings from plastic, though they do sometimes make them from dielectric or insulating materials instead.

Locking features are elements designed to lock in a mating connection so that it properly locks in place. Without locking features, the connection could disconnect before you want it to.

Keying features, also known as polarizing features, make sure that you can only mate a connection if both connections are properly aligned and oriented. Without this feature, users could incorrectly plug in a connector and break it.

Types

The three main types of electronic connectors are as follows: temporary, assembly required, and permanent.

A temporary electronic connector is typically used in portable equipment where the connector’s lifespan will probably be short.

Assembly required electronic connectors are best in applications where more longevity and even the option of removal or replacement down the road is needed.

Permanent connectors are used in applications where they will be expected to perform in one place over the long term.

A further categorization of electrical connectors differentiates them as male and female.

A male connector is used to plug into electrical circuits. Male connectors use metal extensions, like power plug prongs, to connect to the female connector.

A female electronic connector acts as a socket connector. It features a receptacle to receive electrical circuits by connecting to male connectors. One of the most common examples of a female connector socket is the wall plug.

Manufacturers produce many different types of electronic connectors for specific purposes, but a few types are very common in industrial applications. Pin connectors, cable connectors, wire connectors, fiber optic connectors, and amp connectors are among the most common connector types.

Pin connectors are connectors that use pins (sharp pointed and blunt headed pieces of metal wire) to connect electrical circuits. Usually male configured, they generally plug into or otherwise connect to female-configured electrical circuits like sockets. Together, pin and plug connector assemblies can be called socket connectors, pin and socket connectors, or plug and socket connectors.

Cable connectors are a type of electronic connector that manufacturers design specifically to connect cable cords and electronic components. Once joined they can conduct electricity or send communication. Cable connectors are usually composed of a set of flexible wires or stranded wires housed inside a plastic coating. They most often work using a plug or a screw.

Wire connectors are connectors in the very broad category of connectors made out of wire or with wire components.

Fiber optic connectors are connectors that manufacturers create using very fine glass fibers. Fiber optic connectors are perfect for specialized communications setups.

Amp connectors, also known as Amphenol connectors, are connectors that vary in the amount of electric current, or amperage, that they can transfer. They are named after the first company to manufacture them, the Amphenol Corporation. Amp connectors may transmit either AC or DC power. Some of their most common applications include battery, PV array, sub-array, PV, and solar power array connecting.

Some less common types of connectors are DIN connectors, RF connectors, coaxial, and PCB connectors.

DIN connectors are manufactured to standards set by the Deutsches Institut fur Normung (DIN), the German national standard organization.

A coaxial connector has many sub-types, but essentially it is a cable that can maintain a connection.

PCB connectors are connectors designed specifically to work with printed circuit boards. They accommodate the many interconnected and small parts of printed circuit boards.

RF connectors, another type of coaxial connector, work with radio frequencies in a multi-megahertz range.

Other miscellaneous electronic connector types include waterproof connectors and power connectors.

Waterproof connectors work just as they sound; they resist water. Manufacturers can make all different kinds of waterproof connectors, but they work especially well for equipment that could be exposed to the rain, like amplifiers and other audiovisual equipment, as well as tools like wire connectors and plugs for cars, trucks, motorcycles, and marine vehicles.

Power connectors transport large amounts of power from a power source to whatever equipment or electronic devices that require that power.

Advantages

Electronic connectors face competition from alternative methods of establishing connections between electronic components and devices, namely soldering and wireless communication technologies. While soldering is widely used in electronics manufacturing, it lacks the versatility and ease of use offered by electronic connectors. Connectors allow for modular and reconfigurable designs, facilitating easy assembly, disassembly, and maintenance of electronic systems. Unlike soldered connections, connectors permit components to be replaced or upgraded without damaging the circuit board, reducing repair costs and improving overall flexibility.

Wireless communication technologies, such as Bluetooth, Wi-Fi, and NFC, have also emerged as competitors to physical connectors. While wireless connectivity offers convenience and freedom from cables, it does have limitations concerning data transfer rates, range, and susceptibility to interference. In contrast, electronic connectors provide more reliable and secure connections, especially in high-speed data transmission, critical signal integrity, and power delivery applications. Additionally, connectors are not affected by wireless congestion or compatibility issues, making them the preferred choice for many mission-critical and high-performance electronic systems.

The advantages provided by electronic connectors over these other devices are numerous. First, they ensure reliable and stable connections with low resistance, resulting in stable and consistent electrical contact. This is particularly important in applications where data integrity and signal quality are critical. Additionally, connectors enable modularity and reusability, making it easier to assemble and disassemble electronic systems. This modularity enhances flexibility, enabling components to be swapped or upgraded without requiring complex soldering or specialized tools.

Furthermore, electronic connectors simplify maintenance and repair processes, since faulty components can be quickly replaced without the need for extensive rework. This reduces downtime and lowers repair costs. The standardized specifications of connectors also ensure compatibility and interoperability between different devices and brands, fostering a wide range of product choices and promoting a competitive market.

Moreover, connectors provide enhanced safety with reliable mechanical locking mechanisms, reducing the risk of accidental disconnections. Furthermore, physical connectors offer greater security compared to wireless methods, making them preferable for sensitive or critical applications.

Finally, in applications that require high-speed data transmission, connectors offer superior performance compared to wireless alternatives. They can handle higher data rates with lower latency, making them ideal for demanding data-intensive tasks. In summary, electronic connectors outperform soldering and wireless communication technologies in terms of reliability, stability, modularity, maintenance, compatibility, safety, and data transfer rates. Their versatility and superior performance make them the preferred choice for connecting electronic components and devices across a wide range of applications and industries.

Accessories

Various accessories are available to enhance the functionality and protection of electronic connectors. Bushings provide mechanical support and prevent excessive strain on the connector interface. Contacts and terminals establish electrical connections within the connectors. Dust caps shield the mating interface from contaminants when not in use. Adaptors bridge the gap between different connector types or sizes, ensuring compatibility. Wire terminal kits offer a selection of components for custom cable assemblies, while repair kits provide essential items for connector repairs. Determining the needed accessories depends on the application’s requirements, such as environmental conditions and mechanical stress. These accessories can be acquired from manufacturers, distributors, online retailers, electronic component stores, or OEM suppliers. Proper selection and utilization of these accessories contribute to the overall reliability and efficiency of electronic connections.

Proper Care

If you want your electronic connectors to last, you must be very careful with them. This is because they are vulnerable to a number of threats. Temporary electronic connectors are especially vulnerable to attacks by mechanical stress. This is because users so often connect and disconnect them. Over time, the subtle vibration and abrasion that connectors experience can wear them out. In general, electronic connectors are vulnerable to attacks from chemicals, because of their metal components. Metal components like metal contacts, if not properly cared for, can develop rust or become dirty.

The best way to protect your electronic connectors from developing problems like those mentioned above is by regularly checking them for visible damage, regularly checking your equipment for issues that could endanger your electronic connectors (e.g. chemical leaks), and not subjecting your electronic connectors to undue stress or harsh environments. Also, if and when you must clean your connectors, make sure you are using an approved cleaner.

Things to Consider

If you are interested in purchasing one or more electronic connectors, you need to link up with a reliable and well-reviewed electronic connector manufacturer. Since electronic connectors are such common and varied products, a quick Google search will turn up an overwhelming number of hits. While options are great, too many options can just make things confusing. To help you, we have put together a list of some of the best electronic connectors in the United States and Canada. You will find that list, which is complete with profiles and links, towards the middle of this page.

Before you look at our list of electronic connector suppliers, we recommend you take some time to write down your application specifications and requirements. This will help you more quickly decide whether or not a company has potential for you. Remember to write down specifics including your order quantity, your standard requirements, your budget, your delivery preferences, and your delivery deadline.

Once you have written down all of your specifications, check out our list of suppliers. Assess which ones might be a good fit for you, based on your needs. We recommend you narrow it down to three or four top picks. Then, reach out to each company to discuss your application at length. Take note of not only their prices and deals, but also their customer service. It is important to work with a company that is invested in your success. Finally, compare and contrast each conversation, determine which electronic connector company is right for you, and get started.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services